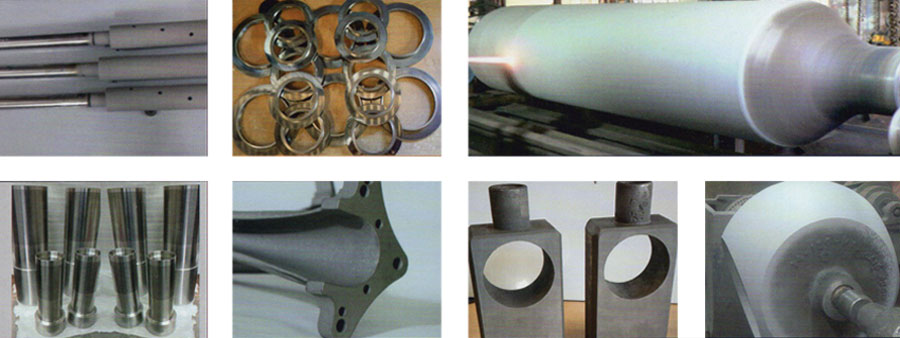

It is a thermal spray coating process essential to increase or restore a component’s surface properties or dimensions. The process improves erosion, wear resistance and corrosion protection. HVOF coating produces the coating of exceptional hardness, excellent adhesion, provides substantial wear resistance and corrosion protection.

We offer the service with the customer-driven approach and to obtain repeatable results. The process of HVOF coating reduces the cost, improves performance, electrical properties. Also, it enables components to operate under high temperatures and harsh chemical environments.

i. Oil Flinger WC Co Coating

ii. PH Bronze Housing Inside Coating

iii. Wood Work Tool NICR Coating

Applications

• Various rolls in steel mill for wear resistance to improve friction coefficientAlloys

• Tungsten Carbide Cobalt